Every summer the Glass Art Society [GAS] holds their annual conference in a different US city. This year it was just a hop-skip-and a jump down the road from us in San Jose and the theme for the conference was "Glass, Art, and Technology." This was a great fit for us and we were pleased they invited Nikolas to speak. His lecture was titled, “Engineering Art.”

In contrast to past lectures—which have been somewhat broader—this presentation focused a bit more pointedly on the challenges that can, and inevitably do, arise when working in glass at the scale we do. And how our toolbox has, and continues to evolve....

Here's Nik to get things started:

"The design of my installations is driven by an interest in sculptural forms and how they relate to architectural space. Technology has nonetheless become a principal element in my work. I take what I see in my head and figure out how to make it rather than looking at the available tools and deciding what to make with them. Tools are things that I develop to solve problems rather than parameters that define what I think I can do. Of course, I can’t just make anything that I want to, without regard for real physical and logistical constraints. I do have a vague idea of what is possible and an attendant “gut feeling.” But I start the process of designing projects in an aspirational mode. The balance of my team's time on projects is spent in a highly iterative and experimental search for solutions to building the original design."

One item in the experimental and problem solving toolbox is the software that the studio uses to make Nikolas’s ideas a reality. Specifically a plug-in for Rhinoceros, which is the 3D CAD program we use. The plugin is called Grasshopper.

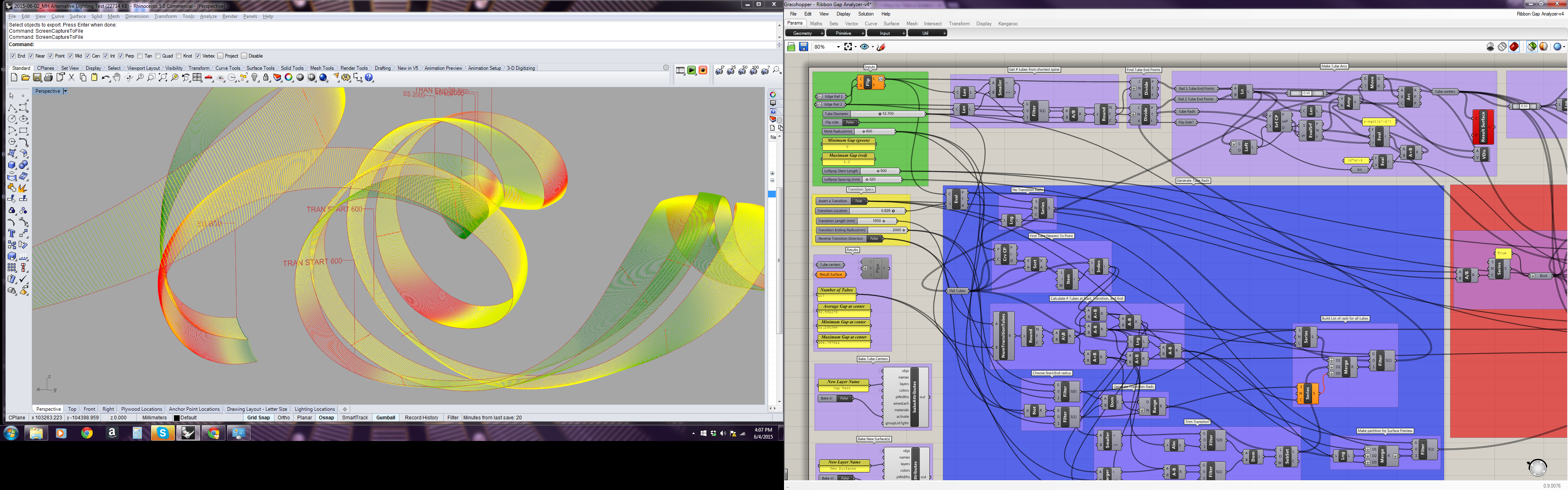

An example of the Grasshopper plugin. The sculpture at left and the "guts" of the software at right. Around the studio, this application is know as The Gapulator. It lets our team study the spacing between the tubes.

An example of the Grasshopper plugin. The sculpture at left and the "guts" of the software at right. Around the studio, this application is know as The Gapulator. It lets our team study the spacing between the tubes.

Rather than struggling to write a layman's explanation of this software, here’s a post with Sam Prest and Dave Johnson discussing and describing the marvels of this technology with Nikolas.

A new tool we'll be working with shortly is a custom tube cutting machine en route from Germany. It will be hooked up to a recent arrival that is the "Accucut Gold Digital Linear Measurement and Positioning System." Stayed tuned for the scoop on this in the coming weeks.

In addition to Nikolas's lecture, GAS featured the studio in the summer issue of their quarterly publication. Glass Art Society News, Summer 2015

AND in conjunction with the presentation, Nikolas was invited to submit an article to the GAS Journal. For those among you who can't get enough of Nikolas Weinstein Studios, his full article is below:

Creating Problems

The design of my installations is driven by an interest in sculptural forms and how they relate to architectural space. Technology has nonetheless become a principal element in my work. I take what I see in my head and figure out how to make it rather than looking at the available tools and deciding what to make with them. Tools are things that I develop to solve problems rather than parameters that define what I think I can do. Of course, I can’t just make anything that I want to, without regard for real physical and logistical constraints. I do have a vague idea of what is possible and an attendant “gut feeling.” But I start the process of designing projects in an aspirational mode. The balance of my time on projects is spent in a highly iterative and experimental search for solutions to building the original design.

While this would seem to be a somewhat backward approach (why not design based on what you know you can build?), it ensures for me innovation in methodology and, consequently, an evolution in aesthetics. When I face problems with no clear roadmap, I experiment. Most of the time it doesn’t work. But one out of every ten times, I see something unexpected and compelling that sparks an idea. I end up building tools and machines with different functions than I originally intended. This forces my work to change, and it allows me to dream of possibilities that are different and more complex than I would have previously imagined.

My first big project came when I was 26. I was very green and had only made blown pieces no bigger than myself. The commission was wildly outsized for where I was in my career but it was one that you just don’t pass up, an installation for the main public space in a Frank O. Gehry building at the center of Berlin next to the Brandenburg Gates. I had no idea what I was doing and spent nearly five years flailing. It was grueling and filled with moments of extreme doubt and deep despair, but I would never trade it in.

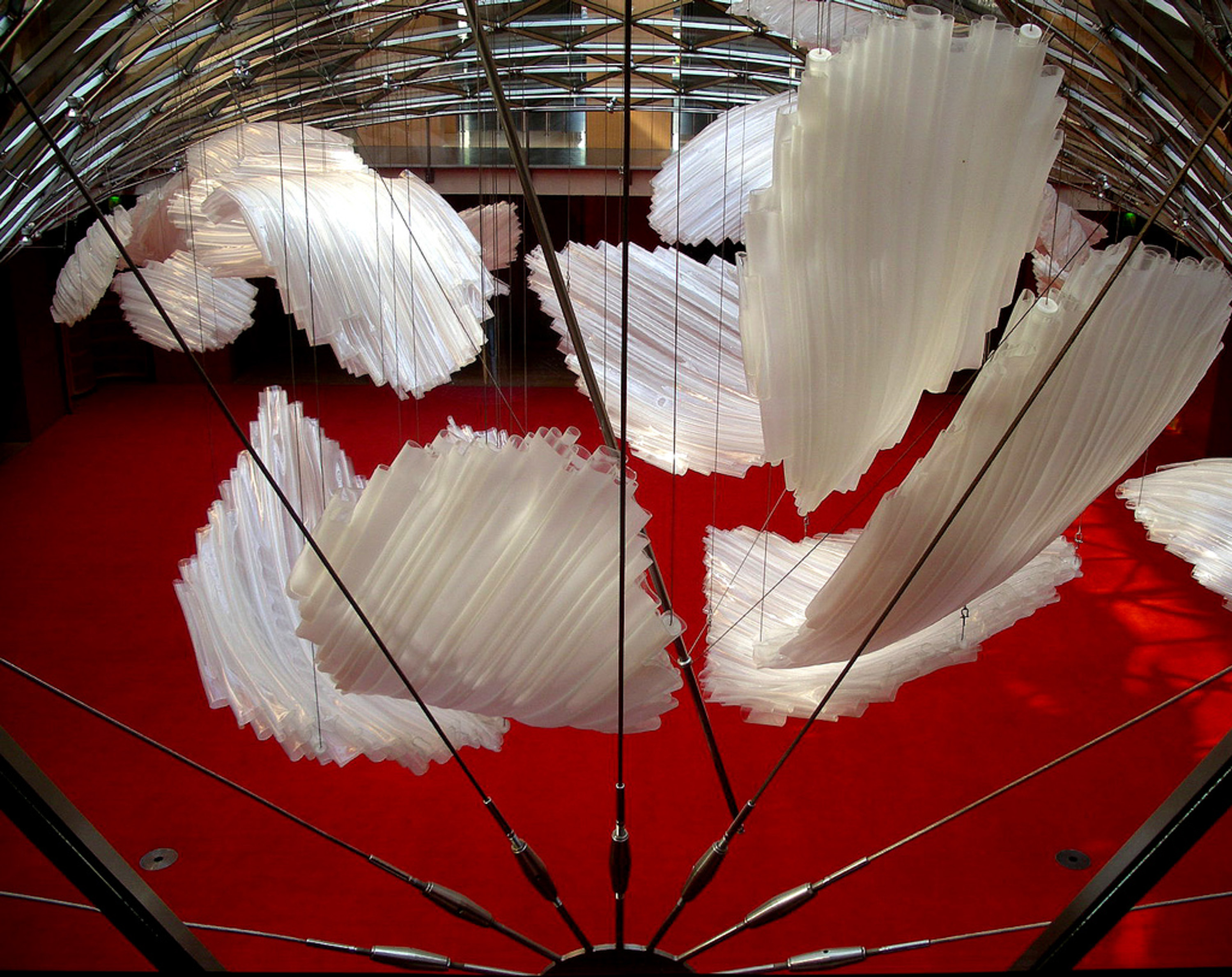

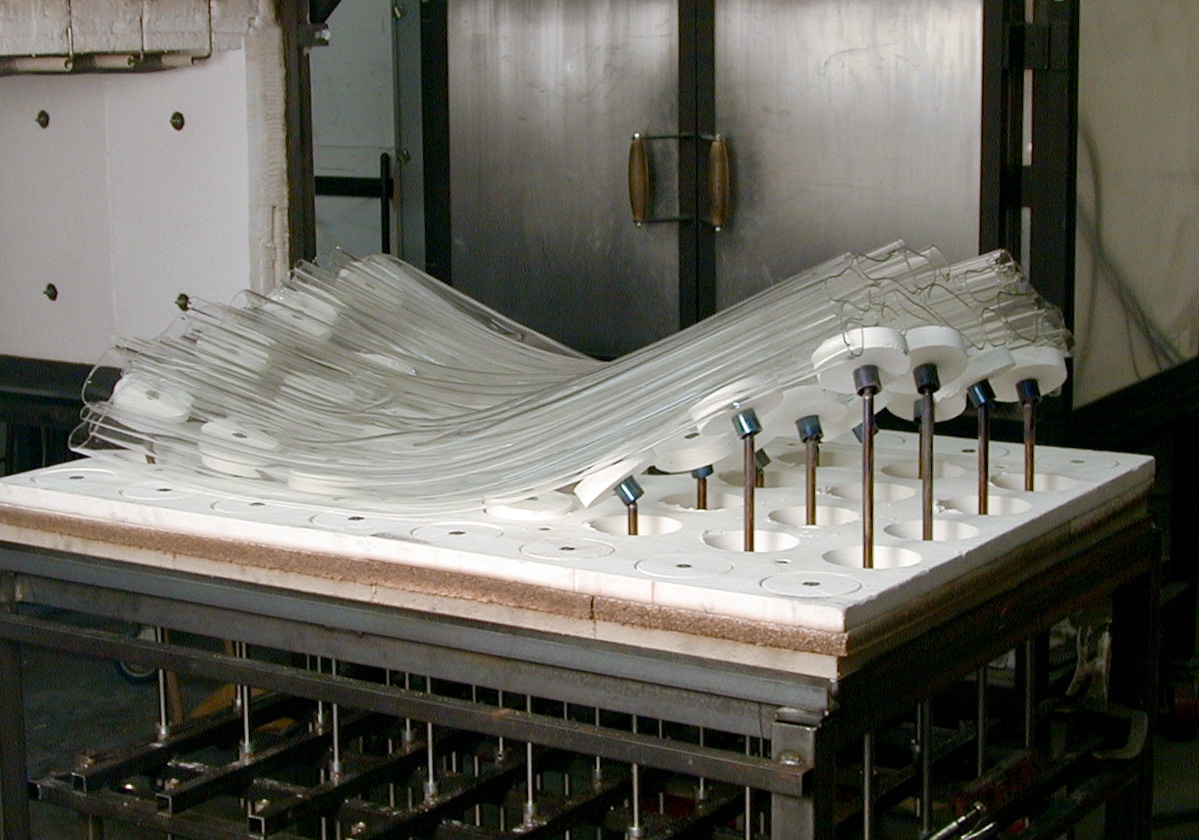

The sculpture was comprised of 36 glass elements the size of small cars that flew through the public atrium of a bank headquarters in three groups. It was about a year into the project when I realized that the scale and complexity of the project was way beyond my ability. I had proposed a cellular matrix of glass tubes as the sculptural material. To build this, we ultimately arrived at a process that required laying individual tubes in parallel on a flat kiln floor and firing them to a temperature hot enough to weld them together, but cool enough to prevent them from collapsing. This yielded a final assembly with structural integrity and a high strength to weight ratio. Once the matrix was fused and annealed, it then had to be shaped over a large mold during a second kiln cycle.

When the project began, I hadn’t appreciated that the process would require two separate cycles nor that the fused tubes would be such a fragile assembly highly prone to failure during the second heating. Even if we had built two kilns instead of one and figured out how to protect the panels in their interim fragile state, the molds were a problem unto themselves. The panels were massive and each one uniquely shaped. I couldn’t even get my head around how to build and store 36 molds the size of cars!

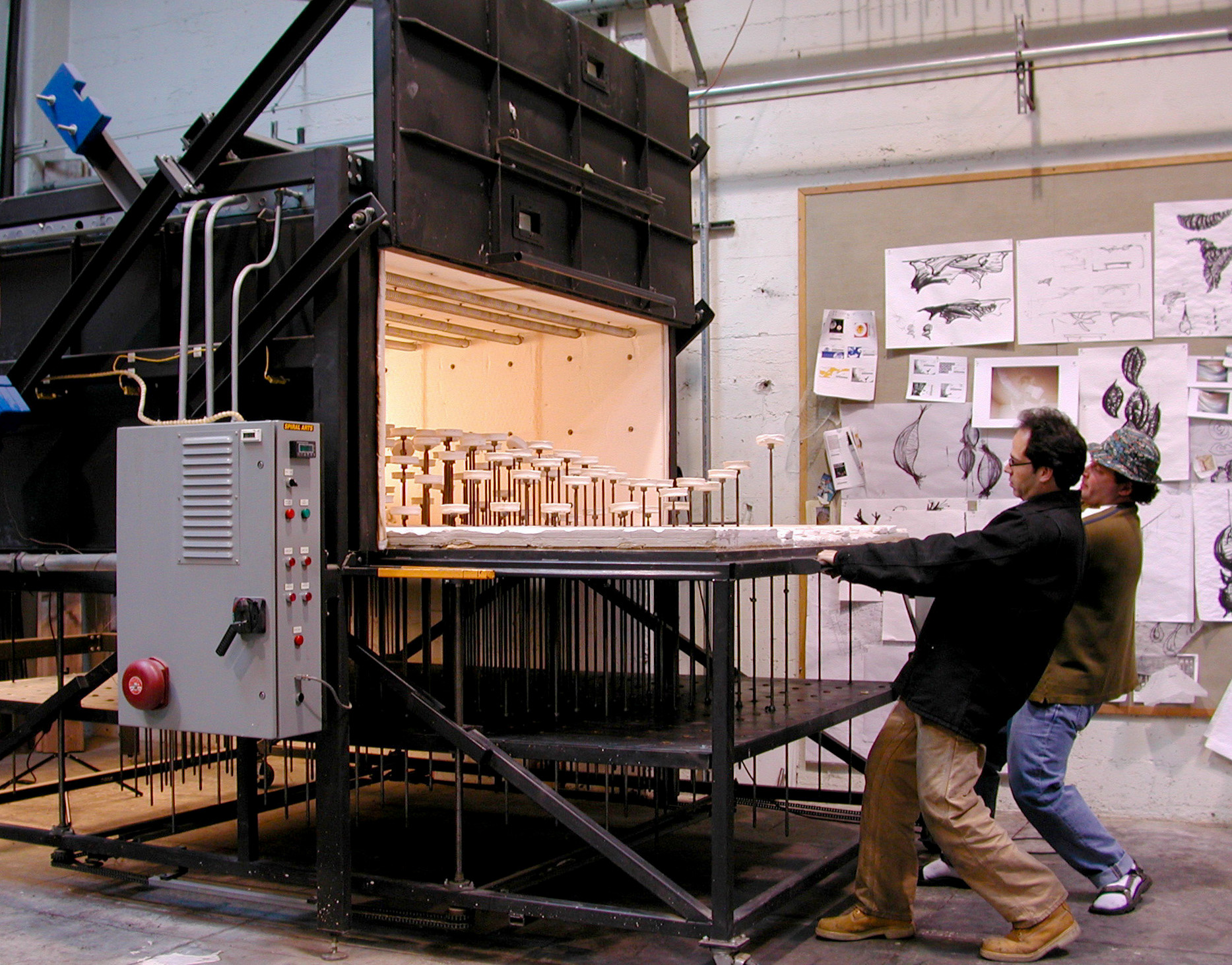

In what was to be the first of many unforeseen and insurmountable-feeling problems, I sought refuge at home with pasta and wine. Lost in an inebriated reverie, I found myself recalling the coffee-table novelty pin molds of the 70s—small, perforated boards filled with pins. When you pushed your hand against one side, it would mold the impression on the reverse. It was a shot in the dark, but I sketched a concept for a kiln bed constructed in a similar manner. My team quickly made a small version to proof-test the idea before fabricating the final kiln, which arrived in a dedicated eighteen-wheeler.

The kiln had a motorized undercarriage that could be programmed and raised to introduce a stippled topography on the interior floor. This allowed us to collapse two kiln cycles into one: beginning with a flat floor and pins unraised, the tubes could be arranged and fused together; then the floor could be actuated to incrementally introduce a mold form at the same rate the glass was bending such that it was continuously supported in its fragile state. Additionally, it allowed us to dispense with inefficient and ungainly molds in favor of an infinitely programmable floor with no thermal mass.

Even though I hadn’t conceived of the kiln before I began the Berlin project, it became its primary tool. Now that I had a kiln with a dynamic and programmable bed, I started to come up with new sculptural shapes that leveraged this technology. When I felt that the kiln was no longer enabling ideas but limiting creativity, I started to hack my hack. To solve other problems that my newer designs introduced, I began drilling holes all over the kiln so that I could remotely pull the glass via cables that ran over weighted pulley systems on the kiln’s exterior.

It is only as I approach the completion of a project that I finally appreciate how to really build it. The majority of the project time is spent making mistakes and learning, and the actual fabrication of the work represents only a small fraction of the effort. The solution gives me new ideas. A completed project is an opportunity to see what has been made possible by the new technology. And so the aspirational cycle begins again, and I design new problems to solve.