In our continuing efforts to put the cart before the horse, we designed another project before we knew exactly how to build it. This is a good thing because it keeps us thinking and naturally derives new constructions and ways to build them. Design should be first.

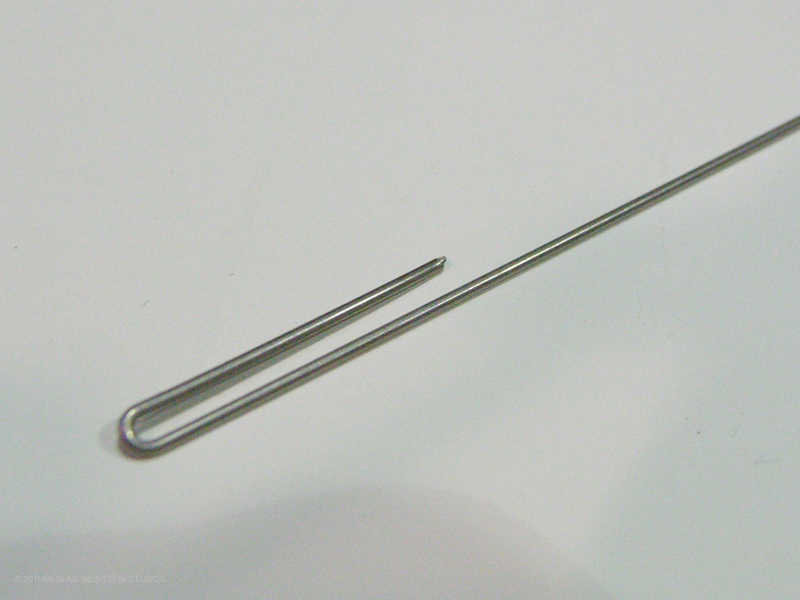

About two years ago we were working on the Shanghai installation which is effectively a highly specialized version of childhood erector sets. The construction matrix is a kit of parts that is infinitely modular. For the main installation in the Grand Lobby, we contracted with a wire manufacturer to make long metal wires with a return on each end that looked somewhat like an opened paper clip. These ran inside each and every tube and were both a means of attachment (these wires poked through the end of the plugs and were captured by a lateral "parent" cable weave) and a secondary safety system (if a tube was damaged, any large bits would be like beads on a necklace).

The wires were quite expensive and arrived in mad jumbles by the box. We dealt with it but when we later started work on the smaller sister installation for the boutique hotel, we needed different sizes and found the cost and mess unconscionable. So we visited our local MacGyver machinist and pyrotechnic fetishist, Kevin Binkert. In this photo, Dave and Binkert talk turkey:

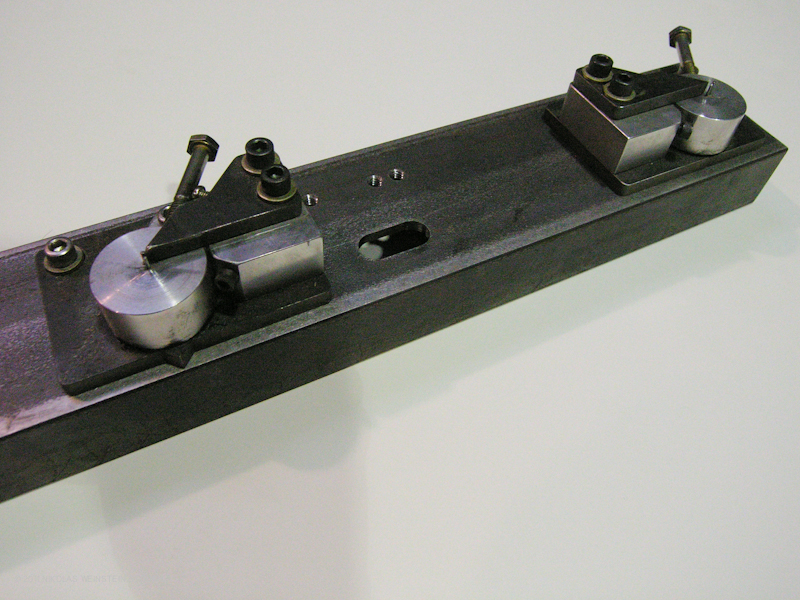

Famed for his flame tornado machine and hydraulic parking kit, Kevin is an unparalleled machinist who does everything from prototype shapes for testing in NASA's wind tunnels to retrofitting San Francisco's Italian-made fire trucks with adapters for the local hydrant fittings. In short, we only wish we had more reasons to call him and go geek-out at his studio. Besides lots of gadgets that we wish had, he has an enormous drill that stands at least ten feet tall and holds bits up to four or five inches. Insane. I believe he mentioned that it was from the Chicago's World's Fair. If it wasn't, it should have been. In the past, he has made for us both mundane small lathe-turned parts to several small machines for super-specialized tasks. Behold, the Binkelator 2000:

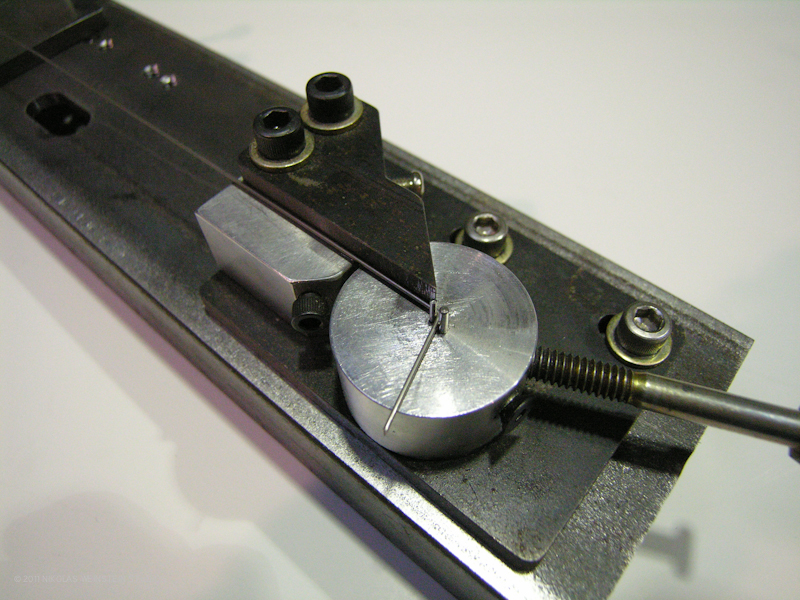

The Binkelator 2000 is an apparently simple but extraordinarily flexible little device. It's hand-actuated but can be infinitely adjusted to create bent wires of any length with just the kind of tight returns that we need to fit through the holes in the injected acrylic plugs that comprise the "knuckle" in our flexible fabric systems. This allowed us to adjust things on the fly as we figured out the exact dimension of the new fabric for this smaller installation. Kevin and I joked that we should market the little bugger. In this image, you can see the wire being bent (mid-process):

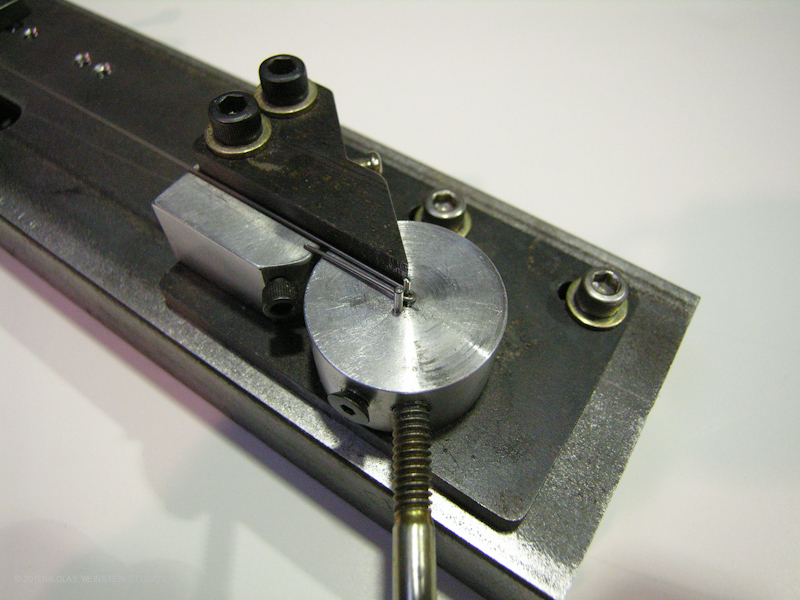

And here it is at the end of the process with the hook fully formed:

If this glass thing doesn't stick, we plan to start supplying Office Depot:

Besides the Binkelator 2000, he authored the Binkelator Fire Polisher 5310 for another project which was based upon larger industrial devices used to fire-polish hundreds and hundreds of tubes:

It has a little chain conveyor with small fingers that carry the tubes past small jets of flame for just the right amount of time to smooth their small ends. One can fill a chute with myriad raw-cut glass tubes and the machine will orient them and feed them into the chute. Of course, it's adjustable so that you can get more or less polishing as well as convey small tubes of variable length and size. And perhaps it's crowning aesthetic glory was a beautiful old black-enameled DC motor from ages past that powered this techie-looking modern gizmo. Of course, I fell in love with the motor and stole it for a home project.